Dryspec® Controls

The Windsor Dryspec® control system is our flagship control system built on a PLC platform. A Factory Talk View SCADA PC provides an intuitive, operator centred, high performance HMI to support product scheduling, fault finding, historical data trending and manual control as required.

Operator controls are customised to meet the needs of the site. Alarm configurations, site layouts, geographic orientation and site-specific equipment are also integrated into the HMI and PLC systems. Additional equipment controls, custom reporting and SQL data exchange can be added if desired.

All PLC components are Allen Bradley Control logix and all other control devices used are freely available.

Call or email us today to discuss for more information.

BDK is Windsor’s modern and visually streamlined control system suitable for small and large sites utilising batch kilns. Colours are used to indicate temperatures and a quick reference layout makes operation simple and easy.

BDK comes complete with Windsor’s standard sensor tracking and trends, troubleshooting and alarm systems along with report and graph output. Dryspec® BDK manages all aspects of fan and temperature control throughout the kiln zone. It can support up to thirty batch kilns and seamlessly integrates with our DryTrack moisture reading software.

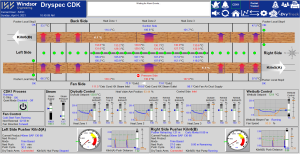

DryspecCDK is used to manage multiple CDK’s, providing maximum information and feedback to allow operators full control and understanding over their drying operation. Dryspec® CDK manages:

DryspecCDK can seamlessly integrate with our DryTrack and PacketTracker software.

DryspecL is a version of our Dryspec software used for our Log Conditioning Chambers. Utilising contrast colours for quick identification of operation, it comes complete with our standard trending software allowing full alarm and troubleshooting, and production reports. DryspecL can run both progressive and batch schedules.